A

MINUTE BRIEF ON ELECTROSTATIC GENERATOR

THEORY OF OPERATION:

Electrostatic generators

come in two categories: friction (triboelectric) and influence

(induction) machines. In both cases the generators convert

mechanical energy into electrical energy by separating electrical

charges and moving them against the electric forces to a collection

point where the charges are stored. The quantity of charges

separated and the amount of force it takes to keep them apart is

equivalent to the stored electrical energy (plus any losses).

TRIBOELECTRIFICATION:

Sliding across a car seat

with nylon pants on generates electricity by what is commonly called

friction. More accurately, the seat and pants are charged by

triboelectrification. When two different materials come into

intimate contact, the surface molecules of the materials share

electrons, that is, the motion of the electrons swarming around in

the molecules cross paths. Some materials have a stronger “hold”

on the electrons than others. When the two materials are pulled

apart, some of the electrons are trapped on the material that has the

stronger hold, giving both materials an equal charge in opposite

polarities. This charge is only on the surface of the materials and

usually, since the triboelectric materials are also insulators,

these charges are not free to move laterally on the surface.

FIGURE 1

The triboelectric

series is a grouping

of materials by their ability to hold excess electrons. A partial

listing from negative to positive (the most negative materials have

the strongest hold on electrons) is: silicone rubber, teflon, PVC,

polyethylene, synthetic rubber, brass, copper, paraffin, steel,

aluminum, wool, nylon, and glass. There are many circumstantial

factors that affect the triboelectric charging process: surface

roughness, humidity, and contamination just to name a few. Due to

the influence of these external factors, there may be instances when

the order listed may be violated (usually only where the two

materials are close together in the series though).

CHARGE BY INDUCTION:

An electrophorus is an

induction generator and will be used for illustrative purposes for

induction because of its simplicity. An electrophorus is a special

capacitor. What makes it special is its dielectric material, and its

removable capacitor plate. The dielectric material is an “electret”

or ferroelectric material with hysteresis. This material has

properties similar to its magnetic counterpart; magnets and

ferromagnetic materials. The electret will become “electrified”

(similar to magnetized) when placed in a strong electric field. This

is due to the electric dipoles in the material aligning themselves

with the applied electric field. Note that in this case, the effect

of the electrification is throughout the material. The dipoles are

"locked" into position by subatomic forces acting within

the material. The electric field will remain about the electret even

after the polarizing field is removed. If an electrically neutral

conducting plate is placed on either side of the electret and a wire

is then connected between them, charges will flow from one plate to

the other until the field created by the displaced charges reaches an

equilibrium with the field across the electret. Once the charges are

in balance, the wire connecting the two plates together can be

removed and the electrophorus looks no different than any other

capacitor charged up to a potential equal to the amount of charge

displaced by the electret’s intrinsic field.

Figure 2

The amount of charge

stored (or displaced) in a capacitor is measured in Coulombs and has

the following mathematical relationship with the capacitance and

voltage:

(equation A)

Q = C V

where: Q = charge in

Coulombs, C = capacitance in Farads, and V = potential in Volts

Also, the capacitor has

energy stored in it when charged. The energy relationship can be

expressed mathematically:

(equation B)

J = (V2

C)/2

where: J = energy in

Joules

Now if the removable

capacitor plate of the electrophorus is removed, the value of the

capacitor decreases inversely with the separation of the plates

(approximately). Also since the wire connecting the two plates was

removed (or the charging voltage source for a capacitor was removed),

the charges on the plates are trapped, and remain constant. If

equation A is rearranged, it can be seen that the voltage on the

capacitor goes up as the capacitance is decreased:

(equation C)

V’ = Q/(C - C)

where: C

= change in capacitance and V’ = new voltage across capacitor .

If the new voltage and

capacitance is substituted into equation B, it can be seen that the

energy stored in the resulting capacitor also went up:

(equation D) J’

= (Q/(C-C))2

(C - C)/2

= Q2 /{2(C -

C)}

where: J’ = new energy

stored in the capacitor

Of course the natural law

of conservation of energy says that you can't get something for

nothing (don't know why it is, it just is), so it must have taken

work to reduce the capacitance. This work is done by separating the

capacitor plates against the electrostatic force pulling them

together. Work can be defined in terms of applying a force through

a distance. This relationship can be expressed mathematically:

(equation E)

J = 1.356 F d

where: J = energy in

Joules, F = force in pounds, and d = distance in feet.

Essentially, induction

generators go about the process of generating static electricity by

repeatedly charging up a capacitor, separating the plates, and

“collecting” the charge off of the plates using a method

described below in the Van de Graaff generator, and discovered by

Michael Faraday in the early nineteenth century. The induction

generators with metallic plates have brushes that come in contact

with them when they are in the “inducing” electric field. This

allows the charges to flow between the capacitor plates to reach

equilibrium. As the plates are moved away from each other, the brush

contacts open up, trapping the charges on the plates. These plates

are moved against the electrostatic force to the collectors where

another brush makes contact with the charged plate and removes the

charges. Once the charges are removed, the plates no longer have a

force between them.

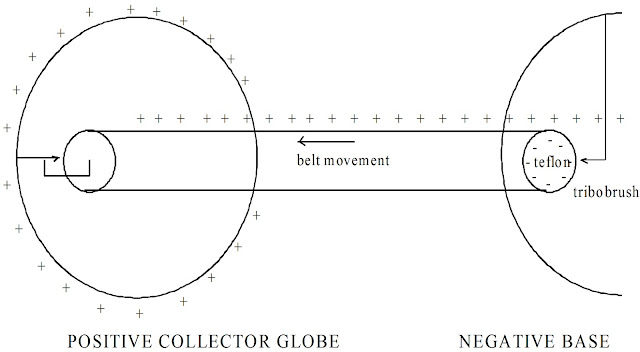

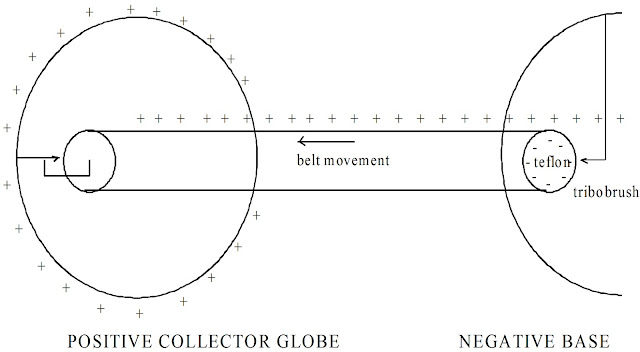

VAN DE GRAAFF

GENERATORS:

The Van de Graaff

generator was invented by Robert J. Van de Graaff in the 1930s (US

patent # 1,991,236). The VG1 is a Van de Graaff generator that

separates the charges by triboelectrification and then uses the

charged drive pulley to induce charges on the transport belt. The

drive pulley on the motor is made of teflon. It drives the rubber

transport belt which is in intimate contact with the pulley.

According to the triboelectric series, teflon is more negative than

rubber. This means that when the up going side of the rubber belt

separates from the teflon drive pulley, a net negative charge exists

on the teflon pulley and a positive one on the rubber belt in the

localized area of separation. Note that since both materials are

insulators, the charges are not free to move on the surface of them.

After the drive pulley has turned a few revolutions, it has a uniform

negative charge all around its circumference. The rubber belt

traveling up to the collector sphere has a positive charge on the

inside of surface of it (side contacting the drive pulley). It

travels up to the collector where the charges are removed as

explained later. When the belt comes down it is neutral (has the

charges on the inside removed).

A conductive brush with

many sharp points is placed on the opposite side of the rubber belt

where the negatively charged pulley and belt are in contact. The

sharp points allow the surrounding air to ionize easily in the

presence of an electric field. The brush has a wire connected to it

which connects to the inside of a metal hemispherical base cover.

Both this cover and the hollow collector sphere at the top of the Van

de Graaff generator behave in such a way that any charge that is

placed in it or taken away from it from the inside, will have an

immediate affect on the apparent total outside charge. That is, any

charge that is brought inside the sphere (or hemisphere) will

immediately be seen as adding to or subtracting from the total charge

on the outside of the sphere even though it still resides inside.

Another thing, if the charge that was brought inside is allowed to

come into contact with the inside of the conductive hollow sphere,

the charge will immediately be transferred to the outside, and no net

charge will then reside inside the sphere. This will be the case no

matter how great the charge outside the sphere or how small the

brought in charge was.

Now at the brush points

where the rubber belt and teflon are in contact, the teflon pulley

has a negative charge and the rubber belt is neutral (the inside of

the belt doesn't obtain the positive charge until the belt and pulley

separate further around the pulley, and the down going side is

neutralized prior to leaving the collector globe). The negative

charge on the pulley will cause electrons to be pushed off of the

brush points on the opposite side of the belt . When the field is

strong enough, electrons from the air molecules

in the vicinity of the brush jump off to the brush points, creating

positively ionized molecules. These molecules are free to move and

are attracted to the negatively charged pulley on the other side of

the belt. They move until they come into intimate contact with the

top side of the belt (since they cannot travel through it). They

become attached to the belt in a way similar to the attachment of the

triboelectric materials to each other, although these attachment

forces are not fully understood. Once attached, it requires a force

to separate the ions from the belt even after the field that caused

them to become attached is removed. It is this force that allows the

ions to remain attached to the belt while it is being moved up to the

collector, and it is this force that when exceeded will cause the

ions to detach and limit the amount of charge the generator can

output. The action is such that a net positive charge per unit

area will reside on the top side of the up going belt. The charges

are then moved up toward the collector sphere against the

electrostatic forces. They are brought inside the collector sphere,

and then are allowed to come in contact with the inside of the sphere

with the aid of a collector brush, at which time they are transferred

to the outside of the collector. The rubber belt is neutralized at

this point and then continues back out of the sphere carrying no

charge out with it. This process continues with the voltage building

up on the sphere by the addition of charge until breakdown occurs.

In the case of the VG1, that is around 70,000 volts.

Figure 3

DISK INDUCTION

MACHINES:

The Wimshurst machine,

named after the British inventor James Wimshurst, is an induction

generator. It has two collectors, one positive and one negative, and

two counter rotating disks with metal sectors attached to them. The

sectors act as movable plates of a capacitor. In operation, an

electric field exists between the two collectors. Two of the sectors

which are displaced off the collector center line by some angular

distance, come into contact with a diagonal shorting bar (also

commonly called neutralizing bars). This bar connects the two plates

together electrically and causes charges to move from one plate to

the other while charging up the capacitance between each plate and

its respective collector. The same thing is happening to the sectors

on the counter rotating disk on the opposite side. As the disks

continue to rotate, the shorting bar brushes break contact and trap

the displaced charges on the sectors. These sectors are then rotated

away from the charged collector that induced the charge on them and

are forced to move (mechanical energy is converted to electrical

energy) toward the other collector which is charged in the same

polarity as the moving sector. When the charged sector reaches the

collector, a collector brush contacts it and transfers the charge in

a similar manner to the description given in the Van de Graaff

generator.

In a “plateless”

generator like the WM1, ions take the place of metallic plates.

Another difference in the WM1 is that it only has one rotating disk,

and it has separate inductor pole pieces instead of using the

collectors as the inductors. Other than this, the principal of

operation is the same as the Wimshurst machine. Ions from air

molecules (oxygen and nitrogen) are formed at the neutralizing combs

due to the high field strength induced by the field pole pieces on

the sharp edges of the combs. These ions are attracted toward the

disk by the pole pieces and get “stuck” on the disk similar to

the ions attaching to the Van de Graaff rubber belt. The disk

rotates around to the collector combs where the charged ions are

stripped off in a manner similar to the metal plate and Van de Graaff

generators, adding the charge to the collectors. As the charge

builds up on the collectors to a level higher than that on the field

pole pieces, the electric field between the probe rods and the

collector pole pieces causes ions to be formed at the probe rod tips.

The ions are mobile and can transfer more charge to the pole

pieces, increasing the field strength. This process continues until

an equilibrium is reached from leakage, corona, or breakdown.

Typically higher voltages

can be generated with a “plateless” generator than one with

plates. This is because the plates have edges and will cause the

field on the plate to be uneven. As the voltage on the plate

increases the higher field strength on the edges will ionize the air

around it and will carry off some of the charge on the plate. This

energy is then lost and winds up as chemical energy (ozone, etc.) or

is lost to heat.

Small Van de Graaff Generator in operation (video)

Induction Machine Operation (Video of Induction Machine)